Cost Comparison Analysis: Traditional vs 3D Printed Shoe Molds

Detailed cost comparison between traditional manufacturing methods and additive manufacturing (3D printing) for shoe mold production, with specific numerical examples illustrating the differences between the two approaches.

| Cost Type | Traditional Method | 3D Printing Method |

|---|---|---|

| Per Mold Development Cost | Approximately $280–1,400 (including wood pattern making, CNC machining, mold replication, texturing, and complete process fees) | Approximately $210–560 (material and energy consumption only, no intermediate processes required) |

| Design Modification Cost | High (requires remaking wood/metal patterns, single modification cost can reach $70–280) | Minimal (digital model adjustment only, negligible cost) |

| Production Cycle Cost | Cycle time 15–20 days, high labor cost proportion (daily labor cost approximately $28–42/person) | Cycle time 6–7 days, labor requirement reduced by 50% or more |

| Material Utilization Rate | Relatively low (waste rate for modeling board, metal materials approximately 30–40%) | High (powder/resin utilization exceeds 95%) |

| Mass Production Cost | Per unit cost can be reduced to $112–210 for large volumes, but small batch customization remains expensive | Significant advantage for small batches (per unit cost stable at $210–560, no minimum order quantity restrictions) |

| Environmental Processing Cost | Requires treatment of chemical etching waste, metal scraps, vân vân., environmental cost per mold approximately $28–70 | No chemical pollution, extremely low waste disposal cost (<$7) |

Cost Comparison Example

Traditional Method: Initial mold development requires $1,120 (including texturing process). If design requires two modifications, total cost increases to $1,260–1,680, with a lead time of 20 days.

3D Printing: Initial mold cost $420, design modifications incur almost no additional cost, total cost remains $420, with a lead time of 7 days.

3D printing demonstrates significant cost advantages (a reduction of 50–70%) in small batch, high-complexity design scenarios, which is particularly suitable for rapid iteration in R&D phases. Traditional methods maintain cost advantages in large-scale standardized production but lack flexibility and environmental friendliness. As 3D printing equipment costs decline (e.g., metal printers decreasing from $490,000 to $420,000 per unit), its economic viability will further improve.

3D Printing vs Traditional Shoe Mold Manufacturing

A comprehensive comparison of modern and traditional manufacturing approaches in the footwear industry

| Comparison Dimension | Traditional Shoe Mold Manufacturing | 3D Printed Shoe Mold Manufacturing |

|---|---|---|

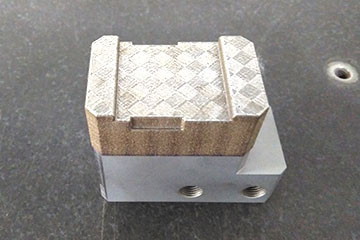

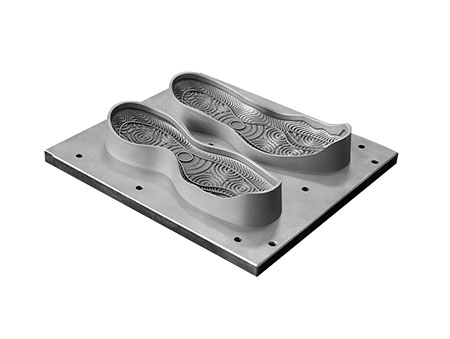

| Pictures of Shoe Molds |  |  |

| Production Process | Requires over 10 process steps including CNC wood mold machining, silicone molding, plaster mold creation, metal casting, chemical etching (texturing), and coating—complex and multi-stage | Direct printing from digital models, eliminating key steps like wood mold fabrication, casting, and chemical etching—highly streamlined process |

| Production Cycle | Longer, typically 15-20 days (includes wood mold processing, casting, etching, vân vân.) | Significantly shorter, typically 5-7 days (direct metal mold printing) |

| Design Freedom | Limited; complex internal structures (e.g., conformal cooling channels) and fine textures are difficult to achieve, reliant on machining capabilities | Extremely high; enables integrated manufacturing of complex curves, honeycomb structures, micro-vent channels, and 0.05mm precision textures without traditional constraints |

| Accuracy & Consistency | Relies on manual skill; poor consistency (typical tolerance ±1mm), prone to deviations due to manual operations | Digitally controlled, accuracy up to ±0.05mm, excellent consistency and repeatability |

| Customization Capability | Difficult to achieve; suitable for large-scale standardized production; high cost and long lead time for design changes | Easily achievable; supports small-batch and personalized customization (e.g., customized lasts based on foot scan data) |

| Environmental Impact | Chemical etching causes pollution, requiring additional environmental treatment facilities | No chemical etching; eco-friendly (digital texturing replaces acid etching), minimal material waste |

| Labor Dependency | Highly reliant on skilled technicians; difficult process inheritance; consistency affected by human factors | Dependent on equipment and software; low reliance on traditional craftsmanship; process parameters can be standardized |

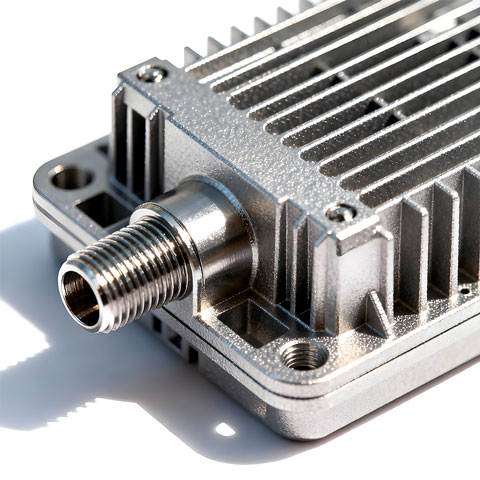

| Initial Investment | Requires multiple specialized machines (CNC, EDM, wire cutting, casting equipment, vân vân.), diverse equipment types | Primarily relies on 3D printing and post-processing equipment; high equipment integration but higher unit cost (e.g., SLM metal 3D printers $0.43-0.5 million/unit) |

Summary

3D printing technology demonstrates significant advantages in shoe mold manufacturing, particularly in reducing lead time (by over 60%), enhancing design freedom (enabling complex structures and fine textures), supporting customization, and improving sustainability compared to traditional methods. It reduces dependency on manual expertise through digital processes and avoids pollution from chemical treatments. However, traditional methods remain valuable for ultra-large-scale standardized production, while 3D printing involves higher initial equipment costs. The two technologies can be applied complementarily based on production needs (volume, complexity, cycle time).

Traditional Method

Best for large-scale standardized production where initial tooling costs can be amortized over high volume runs.

3D Printing

Ideal for prototyping, complex designs, custom footwear, and short production runs with rapid turnaround requirements.