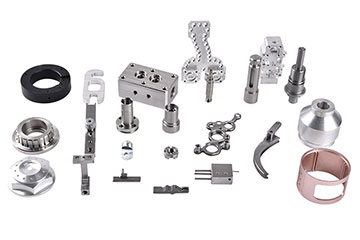

DT CNC Machining Services

Processes, tolerance range, advantages and application areas of CNC machining with different materials

| Common Materials Used | Common Processes | Common Post-Processing | Tolerance Range (mm) | Advantages (Features) | Primary Applications | Maximum Size/Common Size |

|---|---|---|---|---|---|---|

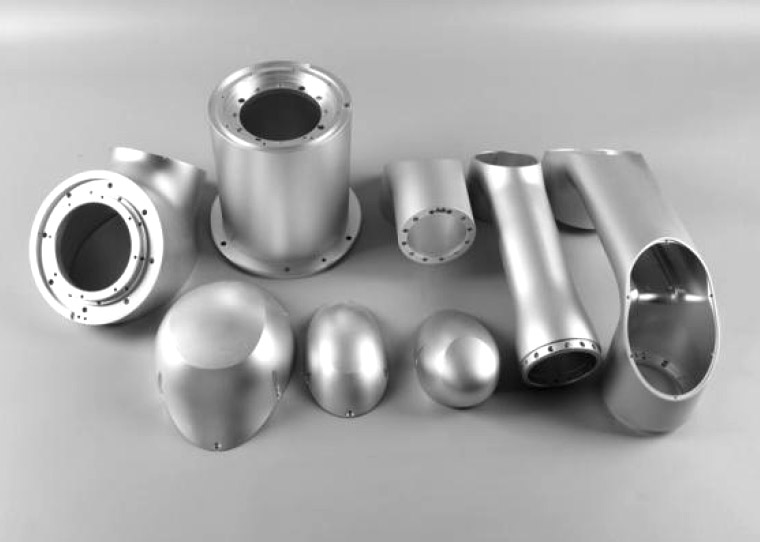

| Aluminum | Precision Machining | Anodizing/Laser Engraving/Silk Screening | ±0.01—±0.05mm | Suitable for various surface treatments | Aerospace, Automotive, Mold Industry | 1600×650×550mm |

| Lathe | Cutting Processing | Anodizing/Sandblasting | ±0.01—±0.05mm | High precision/Excellent surface quality | Auto Parts/Electronic Components | 800×500×500mm |

| Steel | Raw Material Processing | Grinding/Passivation/Laser Engraving/Polishing | ±0.01—±0.05mm | High hardness/Good toughness | Medical Devices, Kitchen Equipment, Automotive & Marine | 800×500×500mm |

| Sheet Metal | Shearing/Bending/Cutting | Powder Coating/Silk Screening/Laser Engraving | ±0.01—±0.05mm | Low development cost/Fast production | Electronics, Telecommunications, Automotive, Computer Chassis | 800×500×500mm |

DT CNC Machining Brief Introduction

We use metallic and plastic materials covering various industries to produce non – standard parts and customized shaped parts through machining processes such as turning, milling, drilling, and assembly.

The 3 – axis, 4 – axis, and 5 – axis CNC machining centers can process various complex shaped parts with multiple precision curved surfaces. The maximum machining size is 1500 * 800 * 500mm, and the machining accuracy can reach ±0.005mm.

The CNC lathe processing is equipped with multi – station turrets and live tool turrets, which can process complex standard and non – standard turned parts such as straight cylinders, inclined cylinders, arcs, various threads, grooves, worms, etc. The maximum machining diameter is 400mm, and the minimum diameter is 1mm.

DT Factory 3D Printers and CNC Machines