SLM Metal 3D Printing Technology Specifications

SLM (Selective Laser Melting) Material Properties and Applications

| Metal 3D Printing Technology | Material Type | Abbreviation | Material Status | Common Post-Processing | Tolerance Range | Processing Advantages | Processing Disadvantages | Application Fields | Maximum Build Size |

|---|---|---|---|---|---|---|---|---|---|

| SLM | Aluminum Alloy | AL | Metal powder | Sandblasting, Anodized Matte Black, Polishing, Electroplating, Passivation, Spray Painting/Powder Coating | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm | Lightweight material, fast heat dissipation, good electrical and thermal conductivity | Support removal is troublesome after printing, rough surface, secondary processing required for high precision requirements | Prototypes, automotive, medical, digital electronics, toys, mechanical equipment, aerospace, etc. | 420*225*260mm |

| Stainless Steel | SS | Metal powder | Sandblasting, Polishing, Electroplating, Passivation, Spray Painting/Powder Coating | Rust-proof, excellent corrosion resistance, ideal for mirror finish effects | |||||

| Titanium Alloy | TC4 | Metal powder | Sandblasting, Polishing, Spray Painting/Powder Coating | High strength with low density, good mechanical properties, toughness and corrosion resistance | 150*150*200mm | ||||

| Die Steel | CX | Metal powder | Sandblasting, Heat Treatment | High toughness and good thermal resistance | Rough surface, requires secondary processing | Plastic, die-casting, shoe mold and other mold industries | 250*250*300mm | ||

| 1.2709 | Metal powder | High toughness and good thermal resistance | |||||||

| Nickel – based Superalloys | GH4169 | Metal powder | Hot isostatic pressing (HIP) , solution treatment and aging, machining | Superior high-temperature strength (>800°C) Excellent oxidation/corrosion resistance Tailorable γ′ precipitation hardening High design freedom for complex geometries | High crack sensitivity, Strict parameter control required, Costly post-processing, High powder cost/reactivity | Aerospace, energy, high-temperature corrosion-resistant industrial systems | 250*250*300mm |

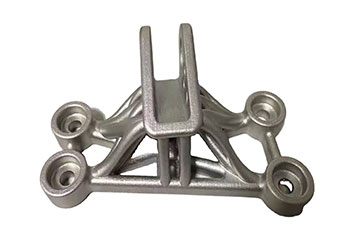

| Metal 3D Printing Technology | SLM |

| Material Type | Aluminum Alloy |

| Abbreviation | AL |

| Material Status | Metal powder |

| Common Post-Processing | Sandblasting, Anodized Matte Black, Polishing, Electroplating, Passivation, Spray Painting/Powder Coating |

| Tolerance Range | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm |

| Processing Advantages | Lightweight material, fast heat dissipation, good electrical and thermal conductivity |

| Processing Disadvantages | Support removal is troublesome after printing, rough surface, secondary processing required for high precision requirements |

| Application Fields | Prototypes, automotive, medical, digital electronics, toys, mechanical equipment, aerospace, etc. |

| Maximum Build Size | 420*225*260mm |

| Metal 3D Printing Technology | SLM |

| Material Type | Stainless Steel |

| Abbreviation | SS |

| Material Status | Metal powder |

| Common Post-Processing | Sandblasting, Polishing, Electroplating, Passivation, Spray Painting/Powder Coating |

| Tolerance Range | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm |

| Processing Advantages | Rust-proof, excellent corrosion resistance, ideal for mirror finish effects |

| Processing Disadvantages | Support removal is troublesome after printing, rough surface, secondary processing required for high precision requirements |

| Application Fields | Prototypes, automotive, medical, digital electronics, toys, mechanical equipment, aerospace, etc. |

| Maximum Build Size | 420*225*260mm |

| Metal 3D Printing Technology | SLM |

| Material Type | Titanium Alloy |

| Abbreviation | TC4 |

| Material Status | Metal powder |

| Common Post-Processing | Sandblasting, Polishing, Spray Painting/Powder Coating |

| Tolerance Range | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm |

| Processing Advantages | High strength with low density, good mechanical properties, toughness and corrosion resistance |

| Processing Disadvantages | Support removal is troublesome after printing, rough surface, secondary processing required for high precision requirements |

| Application Fields | Prototypes, automotive, medical, digital electronics, toys, mechanical equipment, aerospace, etc. |

| Maximum Build Size | 150*150*200mm |

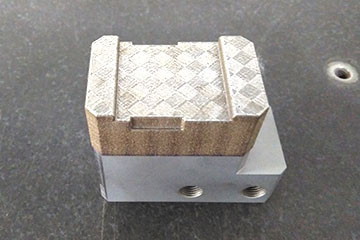

| Metal 3D Printing Technology | SLM |

| Material Type | Die Steel |

| Abbreviation | CX |

| Material Status | Metal powder |

| Common Post-Processing | Sandblasting, Heat Treatment |

| Tolerance Range | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm |

| Processing Advantages | High toughness and good thermal resistance |

| Processing Disadvantages | Rough surface, requires secondary processing |

| Application Fields | Plastic, die-casting, shoe mold and other mold industries |

| Maximum Build Size | 250*250*300mm |

| Metal 3D Printing Technology | SLM |

| Material Type | Die Steel |

| Abbreviation | 1.2709 |

| Material Status | Metal powder |

| Common Post-Processing | Sandblasting, Heat Treatment |

| Tolerance Range | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm |

| Processing Advantages | High toughness and good thermal resistance |

| Processing Disadvantages | Rough surface, requires secondary processing |

| Application Fields | Plastic, die-casting, shoe mold and other mold industries |

| Maximum Build Size | 250*250*300mm |

| Metal 3D Printing Technology | SLM |

| Material Type | Nickel – based Superalloys |

| Abbreviation | GH4169 |

| Material Status | Metal powder |

| Common Post-Processing | Hot isostatic pressing (HIP) , solution treatment and aging, machining |

| Tolerance Range | Based on 3D drawing assessment, post-printing accuracy for smaller dimensions (within 50mm) is approximately ±0.2mm. Secondary precision machining required for accuracy below ±0.1mm |

| Processing Advantages | Superior high-temperature strength (>800°C) Excellent oxidation/corrosion resistance Tailorable γ′ precipitation hardening High design freedom for complex geometries |

| Processing Disadvantages | High crack sensitivity, Strict parameter control required, Costly post-processing, High powder cost/reactivity |

| Application Fields | Aerospace, energy, high-temperature corrosion-resistant industrial systems |

| Maximum Build Size | 250*250*300mm |

Plastic 3D Printing Technologies Comparison

Material Properties and Applications of Various Plastic 3D Printing Methods

| 3D Printing Technology | Material Category | Material Name | Color Option | Post-Processing | Dimensional Accuracy | Advantages | Limitations | Applications | Max Build Size (mm) |

|---|---|---|---|---|---|---|---|---|---|

| SLA | Photopolymer Resin | ABS-like | White | Sanding, Bead Blasting, Painting, Silkscreen, Vacuum Plating, UV Coating, Laser Engraving | ±0.2-0.5mm | Cost-effective, Fast turnaround, Assembling capability, No size restrictions | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes | Prototypes, Automotive, Medical, Consumer Electronics, Toys, Machinery, Aerospace | 1200×600×400 |

| ABS-like | Yellow | Cost-effective, Fast turnaround, Assembling capability, No size restrictions | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes | ||||||

| ABS-like | Green | Cost-effective, Fast turnaround, Assembling capability, No size restrictions | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes | ||||||

| ABS-like | Black | Cost-effective, Fast turnaround, Assembling capability, No size restrictions | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes | ||||||

| SLA | Photopolymer Resin | PC-like | Transparent | Sanding, Polishing, Bead Blasting, Painting, Silkscreen, Vacuum Plating, Laser Engraving | ±0.2-0.5mm | Affordable pricing, Quick cycle time, Assembly possible, Unlimited size capacity | 90% transparency max (vs CNC machining), Limited optical clarity | Transparent parts, Lampshades, Display models | 600×600×400 |

| PC-like | Semi-Transparent | Affordable pricing, Quick cycle time, Assembly possible, Unlimited size capacity | 90% transparency max (vs CNC machining), Limited optical clarity | ||||||

| SLS | Nylon | PA | Black/White | None | ±0.3mm | Wear-resistant, High temperature tolerance | Rough surface finish, Not suitable for bonding | Home Appliances, Power Tools, Automotive Components | 200×200×100 |

| DLP | Red Wax | – | Red | None | ±0.1mm | High precision, Fine detail capability | Higher cost, Limited build size | Jewelry, Accessories, Animation Models | 200×100×200 |

| FDM | Inkjet Fused Filament | PLA, TPU, PA, carbon fiber, PC, ABS | Multiple colors available | Grinding, polishing, sandblasting, spraying, silk – screening, laser engraving, etc. | ±0.05mm | Multiple colors, various materials, cost – effective, no size restrictions | Rough surface | Crafts, lighting fixtures, home furnishings, animation and comics, etc. | 1000*1000*500 |

| 3D Printing Technology | SLA |

| Material Category | Photopolymer Resin |

| Material Name | ABS-like |

| Color Option | White |

| Post-Processing | Sanding, Bead Blasting, Painting, Silkscreen, Vacuum Plating, UV Coating, Laser Engraving |

| Dimensional Accuracy | ±0.2-0.5mm |

| Advantages | Cost-effective, Fast turnaround, Assembling capability, No size restrictions |

| Limitations | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes |

| Applications | Prototypes, Automotive, Medical, Consumer Electronics, Toys, Machinery, Aerospace |

| Max Build Size (mm) | 1200×600×400 |

| 3D Printing Technology | SLA |

| Material Category | Photopolymer Resin |

| Material Name | ABS-like |

| Color Option | Yellow |

| Post-Processing | Sanding, Bead Blasting, Painting, Silkscreen, Vacuum Plating, UV Coating, Laser Engraving |

| Dimensional Accuracy | ±0.2-0.5mm |

| Advantages | Cost-effective, Fast turnaround, Assembling capability, No size restrictions |

| Limitations | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes |

| Applications | Prototypes, Automotive, Medical, Consumer Electronics, Toys, Machinery, Aerospace |

| Max Build Size (mm) | 1200×600×400 |

| 3D Printing Technology | SLA |

| Material Category | Photopolymer Resin |

| Material Name | ABS-like |

| Color Option | Green |

| Post-Processing | Sanding, Bead Blasting, Painting, Silkscreen, Vacuum Plating, UV Coating, Laser Engraving |

| Dimensional Accuracy | ±0.2-0.5mm |

| Advantages | Cost-effective, Fast turnaround, Assembling capability, No size restrictions |

| Limitations | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes |

| Applications | Prototypes, Automotive, Medical, Consumer Electronics, Toys, Machinery, Aerospace |

| Max Build Size (mm) | 1200×600×400 |

| 3D Printing Technology | SLA |

| Material Category | Photopolymer Resin |

| Material Name | ABS-like |

| Color Option | Black |

| Post-Processing | Sanding, Bead Blasting, Painting, Silkscreen, Vacuum Plating, UV Coating, Laser Engraving |

| Dimensional Accuracy | ±0.2-0.5mm |

| Advantages | Cost-effective, Fast turnaround, Assembling capability, No size restrictions |

| Limitations | Brittle material, Heat resistance \\\~40°C, Yellowing over time without coating, Limited reuse of threaded holes |

| Applications | Prototypes, Automotive, Medical, Consumer Electronics, Toys, Machinery, Aerospace |

| Max Build Size (mm) | 1200×600×400 |

| 3D Printing Technology | SLA |

| Material Category | Photopolymer Resin |

| Material Name | PC-like |

| Color Option | Transparent |

| Post-Processing | Sanding, Polishing, Bead Blasting, Painting, Silkscreen, Vacuum Plating, Laser Engraving |

| Dimensional Accuracy | ±0.2-0.5mm |

| Advantages | Affordable pricing, Quick cycle time, Assembly possible, Unlimited size capacity |

| Limitations | 90% transparency max (vs CNC machining), Limited optical clarity |

| Applications | Transparent parts, Lampshades, Display models |

| Max Build Size (mm) | 600×600×400 |

| 3D Printing Technology | SLA |

| Material Category | Photopolymer Resin |

| Material Name | PC-like |

| Color Option | Semi-Transparent |

| Post-Processing | Sanding, Polishing, Bead Blasting, Painting, Silkscreen, Vacuum Plating, Laser Engraving |

| Dimensional Accuracy | ±0.2-0.5mm |

| Advantages | Affordable pricing, Quick cycle time, Assembly possible, Unlimited size capacity |

| Limitations | 90% transparency max (vs CNC machining), Limited optical clarity |

| Applications | Transparent parts, Lampshades, Display models |

| Max Build Size (mm) | 600×600×400 |

| 3D Printing Technology | SLS |

| Material Category | Nylon |

| Material Name | PA |

| Color Option | Black/White |

| Post-Processing | None |

| Dimensional Accuracy | ±0.3mm |

| Advantages | Wear-resistant, High temperature tolerance |

| Limitations | Rough surface finish, Not suitable for bonding |

| Applications | Home Appliances, Power Tools, Automotive Components |

| Max Build Size (mm) | 200×200×100 |

| 3D Printing Technology | DLP |

| Material Category | Red Wax |

| Material Name | – |

| Color Option | Red |

| Post-Processing | None |

| Dimensional Accuracy | ±0.1mm |

| Advantages | High precision, Fine detail capability |

| Limitations | Higher cost, Limited build size |

| Applications | Jewelry, Accessories, Animation Models |

| Max Build Size (mm) | 200×100×200 |

| 3D Printing Technology | FDM |

| Material Category | Inkjet Fused Filament |

| Material Name | PLA, TPU, PA, carbon fiber, PC, ABS |

| Color Option | Multiple colors available |

| Post-Processing | Grinding, polishing, sandblasting, spraying, silk – screening, laser engraving, etc. |

| Dimensional Accuracy | ±0.05mm |

| Advantages | Multiple colors, various materials, cost – effective, no size restrictions |

| Limitations | Rough surface |

| Applications | Crafts, lighting fixtures, home furnishings, animation and comics, etc. |

| Max Build Size (mm) | 1000*1000*500 |