| Material | Stainless Steel | |

|---|---|---|

| Grade | 316L | |

| Main Composition | Fe: bal | |

| Cr: 16~18% | ||

| Ni: 10~14% | ||

| Mo: 2~3% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 16~18 | |

| Tap Density (g/cm³) | 4.5~4.7 | |

| Apparent Density (g/cm³) | 4.0~4.2 | |

| Density | Density | 7.9 |

| Sample Theoretical Density | >99% | |

| As-built Properties | Hardness | 13~15HRC |

| Tensile Strength/Rm | 580MPa | |

| Yield Strength/Rp0.2 | 490MPa | |

| Elongation at Break/A | 32% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Heat-treated Properties | Hardness | 13~15HRC |

| Tensile Strength/Rm | 670MPa | |

| Yield Strength/Rp0.2 | 550MPa | |

| Elongation at Break/A | 35% | |

| Reduction of Area/Z | 45% | |

| Elastic Modulus/E | 185GPa | |

| Material | Stainless Steel | |

|---|---|---|

| Grade | 17-4PH | |

| Main Composition | Fe: bal | |

| Cr: 15.5~17.5% | ||

| Ni: 3~5% | ||

| Cu: 3~5% | ||

| Physical Properties | Powder Particle Size | 5-53 μm |

| Flowability (s/50g) | 16~18 | |

| Tap Density (g/cm³) | 4.5~4.7 | |

| Apparent Density (g/cm³) | 4.0~4.2 | |

| Density | Density | 7.9 |

| Sample Theoretical Density | >99% | |

| As-built Properties | Hardness | 18~22HRC |

| Tensile Strength/Rm | 860MPa | |

| Yield Strength/Rp0.2 | 700MPa | |

| Elongation at Break/A | 19% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Heat-treated Properties | Hardness | 32~42HRC |

| Tensile Strength/Rm | 1340MPa | |

| Yield Strength/Rp0.2 | 1210MPa | |

| Elongation at Break/A | 13% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Material | Mold Steel | |

|---|---|---|

| Grade | 18Ni300 | |

| Main Composition | Fe: bal | |

| Ni: 17~19% | ||

| Co: 8.5~9.5% | ||

| Mo: 4.5~5.2% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 19.3 | |

| Tap Density (g/cm³) | 4.8~4.9 | |

| Apparent Density (g/cm³) | 4.2~4.5 | |

| Density | Density | 8.09 |

| Sample Theoretical Density | >99% | |

| As-built Properties | Hardness | 38 ~42 HRC |

| Tensile Strength/Rm | 1177MPa | |

| Yield Strength/Rp0.2 | 980MPa | |

| Elongation at Break/A | 8% | |

| Reduction of Area/Z | 40% | |

| Elastic Modulus/E | 113GPa | |

| Heat-treated Properties | Hardness | 54-57HRC |

| Tensile Strength/Rm | 2163MPa | |

| Yield Strength/Rp0.2 | 1920MPa | |

| Elongation at Break/A | 2.50% | |

| Reduction of Area/Z | 10% | |

| Elastic Modulus/E | 125GPa | |

| Material | Titanium Alloy | |

|---|---|---|

| Grade | TC4 | |

| Main Composition | Ti: bal | |

| Al: 5.5~6.75% | ||

| V: 3.5~4.5% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 36~40 | |

| Tap Density (g/cm³) | 2.7~2.85 | |

| Apparent Density (g/cm³) | 2.3~2.5 | |

| Density | Density | 4.56 |

| Sample Theoretical Density | >99% | |

| As-built Properties | Hardness | 380HV |

| Tensile Strength/Rm | 1000MPa | |

| Yield Strength/Rp0.2 | 950MPa | |

| Elongation at Break/A | 7% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | 105GPa | |

| Heat-treated Properties | Hardness | 350HV |

| Tensile Strength/Rm | 1000 | |

| Yield Strength/Rp0.2 | 825 | |

| Elongation at Break/A | 14% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | 125GPa | |

| Material | Aluminum Alloy | |

|---|---|---|

| Grade | AlSi10Mg | |

| Main Composition | Al: bal | |

| Si: 9.0~11% | ||

| Mg: 0.2~0.45% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 150 | |

| Tap Density (g/cm³) | 1.55 | |

| Apparent Density (g/cm³) | 1.3~1.45 | |

| Density | Density | 2.7 |

| Sample Theoretical Density | ≥99.3% | |

| As-built Properties | Hardness | / |

| Tensile Strength/Rm | 420MPa | |

| Yield Strength/Rp0.2 | 240MPa | |

| Elongation at Break/A | 5.50% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | 44GPa | |

| Heat-treated Properties | Hardness | / |

| Tensile Strength/Rm | 330MPa | |

| Yield Strength/Rp0.2 | 210MPa | |

| Elongation at Break/A | 11.00% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Material | Aluminum Alloy (Anodized) | |

|---|---|---|

| Grade | 6061 | |

| Main Composition | Al: bal | |

| Mg: 0.8~1.2% | ||

| Si: 0.4~0.8% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 120 | |

| Tap Density (g/cm³) | 1.5 | |

| Apparent Density (g/cm³) | 1.2 | |

| Density | Density | 2.7 |

| Sample Theoretical Density | ≥98% | |

| As-built Properties | Hardness | / |

| Tensile Strength/Rm | 290MPa | |

| Yield Strength/Rp0.2 | 250MPa | |

| Elongation at Break/A | 14% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Heat-treated Properties | Hardness | / |

| Tensile Strength/Rm | / | |

| Yield Strength/Rp0.2 | / | |

| Elongation at Break/A | / | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Material | Copper Chromium Zirconium Alloy | |

|---|---|---|

| Grade | CuCrZr | |

| Main Composition | Cu: bal(≥98%) | |

| Cr: 0.5~1.5% | ||

| Zr: 0.05~0.25% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 18~22 | |

| Tap Density (g/cm³) | 5.2 | |

| Apparent Density (g/cm³) | 4.0~4.4 | |

| Density | Density | 8.9 |

| Sample Theoretical Density | ≥99.3% | |

| As-built Properties | Hardness | 90HV |

| Tensile Strength/Rm | 350MPa | |

| Yield Strength/Rp0.2 | 250MPa | |

| Elongation at Break/A | 30% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Heat-treated Properties | Hardness | 90HV |

| Tensile Strength/Rm | 543MPa | |

| Yield Strength/Rp0.2 | 432 MPa | |

| Elongation at Break/A | 21% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | Conductivity IACS: ≥85% | |

| Material | Tin Bronze Alloy | |

|---|---|---|

| Grade | CuSn10 | |

| Main Composition | Cu: bal | |

| Sn: 9.0~11% | ||

| Zn: 0.5% | ||

| Physical Properties | Powder Particle Size | 15-53 μm |

| Flowability (s/50g) | 16 | |

| Tap Density (g/cm³) | 5.8 | |

| Apparent Density (g/cm³) | 4.2~4.8 | |

| Density | Density | 8.64 |

| Sample Theoretical Density | ≥98% | |

| As-built Properties | Hardness | 150HV |

| Tensile Strength/Rm | 578MPa | |

| Yield Strength/Rp0.2 | 470MPa | |

| Elongation at Break/A | 23.90% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Heat-treated Properties | Hardness | / |

| Tensile Strength/Rm | / | |

| Yield Strength/Rp0.2 | / | |

| Elongation at Break/A | / | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Material | Nickel-based Superalloy | |

|---|---|---|

| Grade | GH4169 | |

| Main Composition | Ni: 50~55% | |

| Cr: 17~21% | ||

| Fe: bal | ||

| Physical Properties | Powder Particle Size | |

| Flowability (s/50g) | 14 | |

| Tap Density (g/cm³) | 4.9 | |

| Apparent Density (g/cm³) | 4.41 | |

| Density | Density | 8.24 |

| Sample Theoretical Density | ≥99% | |

| As-built Properties | Hardness | 220HV |

| Tensile Strength/Rm | 1158MPa | |

| Yield Strength/Rp0.2 | 914MPa | |

| Elongation at Break/A | 14% | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

| Heat-treated Properties | Hardness | / |

| Tensile Strength/Rm | / | |

| Yield Strength/Rp0.2 | / | |

| Elongation at Break/A | / | |

| Reduction of Area/Z | / | |

| Elastic Modulus/E | / | |

We own dozens of SLM 3D printers for industrial use.

And the main commonly used metallic materials are these:

- Aluminum Alloy (6061 / AlSi10Mg / 7075)

- Stainless Steel (316L / 304L / 17-4 / 347)

- Titanium Alloy (TC4 / TA1)

- Mold Steel (S136/HB/CX/1.2709)

- Nickel-rich Alloy (GH4169 / GH3128 / INCONEL625)

- Brass Alloy (CuCrZr / Tin Bronze)

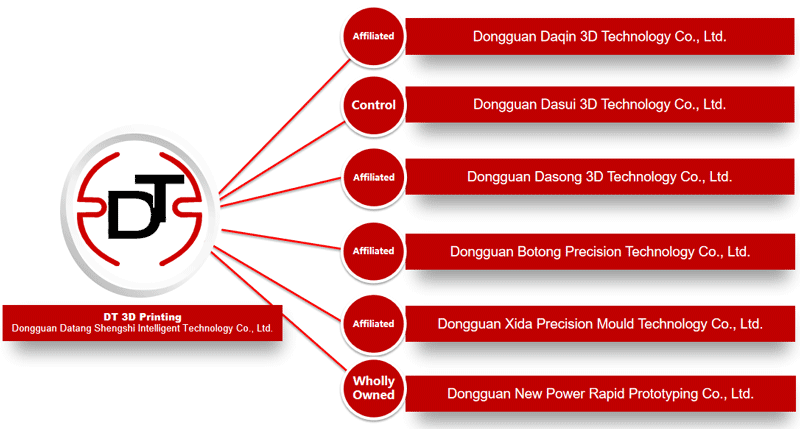

DT is a one – stop 3D printing platform.

Not only because we have dozens of SLM 3D printers and plastic 3D printers, but also, we have invested in 6 3D – printing and CNC machining related factories.

So if you have personalized requirements regarding materials and want to have customized solutions, you can contact us directly.