SLM vs. DMLS 3D Printing Technology Basics

| Comparison Dimension | SLM (選択的レーザー溶融) | DMLS (金属レーザー直接焼結) |

|---|---|---|

| Definition | A metal additive manufacturing (AM) technology that uses a high-power laser to fully melt metal powder, building up parts layer-by-layer to form dense, solid metal components. | A metal 3D printing technology where a laser partially melts and sinters metal powder particles, causing them to fuse on a surface level to create near-net-shape parts. |

| Working Principle |

1. Powder Recoating: A recoater blade spreads a thin, even layer of metal powder across the build platform. 2. Laser Melting: A high-energy laser beam selectively scans and fully melts the powder based on CAD cross-section data. 3. Layer-by-Layer Buildup: The build platform descends, and the process repeats until the part is complete. |

1. Powder Layering: Metal powder is evenly distributed across the build platform. 2. Laser Sintering: A laser beam scans to partially melt powder particles, sintering them together through surface fusion. 3. Solidification: The sintered layer cools and solidifies, and the process repeats for subsequent layers. |

| Characteristics of Products Printed |

– Very high density (near 100%), excellent mechanical properties. – Higher surface quality (Ra 5-15 μm). – Primarily suited for single-metal alloys (e.g., Titanium alloys, Aluminum alloys). – Often requires 後処理 (e.g., heat treatment, 研磨) to improve surface finish. |

– Slightly lower density (95-99%) with minimal porosity. – Higher surface roughness (Ra 10-25 μm). – Compatible with multi-material powders and high-temperature alloys (e.g., Nickel-based superalloys, Stainless steel). – Lower residual stress, but often requires support structures to prevent warping. |

| Industrial 3D Printer: SLM vs. DMLS |  SLM 3D プリンター (Picture from dt3dprint.com) The cost of SLM 3D Printer is very high, and SLM is suitable for mass production |  DMLS 3D Printer (Picture from jgvogel.cn) The cost of DMLS 3D Printer is much lower, and DMLS is suitable for customization. |

| Extensiveness of Application |

SLM has a wider application scope. Due to its characteristics of high density and high strength, it has become the preferred technology in fields such as aerospace, medical implants, and heavy – duty automotive components. さらに, it is more suitable for large – scale production. |

DMLS overall market share is relatively low. It is applicable to specific scenarios. It has advantages in multi-material alloys and complex precision structures, such as medical dental implants and sensor housings. |

SLM vs. DMLS Technology Application Comparison and Selection Recommendations

Comprehensive comparison and application analysis of Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS)

Choosing between SLM (選択的レーザー溶融) and DMLS (金属レーザー直接焼結) requires a comprehensive evaluation of material properties, performance requirements, geometric complexity, and cost-effectiveness.

This guide will help you understand the differences, suitable applications, and selection criteria for both technologies to make the optimal decision for your project.

SLM vs. DMLS Application Comparison

| Application Field | SLM (選択的レーザー溶融) Typical Applications | DMLS (金属レーザー直接焼結) Typical Applications |

|---|---|---|

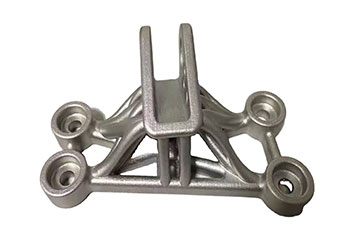

🏭航空宇宙 | Engine brackets, wing spars, rocket fuel nozzles, and other high-strength load-bearing structures | Engine turbine blades, fuel injectors, heat exchangers, and other high-temperature functional components |

🏥医学 & Healthcare | Pure titanium joint implants, orthopedic plates, cranial implants, and other dense biomedical implants | Dental implants, surgical guides, bionic bone scaffolds, and other multi-material custom tools |

🚗 Automotive | Steering Systems: Steering gear housing (AlSi10Mg aluminum alloy) Engine Components: Cylinder heads with optimized cooling channels Custom pistons with internal lattice structures Lightweight Structures: Suspension elements (titanium alloys) Battery brackets and enclosures for EVs (aluminum series) Tooling & Fixtures: Custom jigs and fixtures for assembly lines End-of-arm tooling for robotics | Turbocharging Systems: Turbocharger blades with complex internal cooling channels (Haynes 282, インコネル)

Functional Testing Parts: Starter motor bushes (wear-resistant alloys) Transmission test components Thermal Management: Heat exchangers for battery thermal systems (copper alloys) Coolant manifolds with integrated pathways Performance Components: Exhaust manifolds for racing applications (heat-resistant superalloys) Lightweight brackets for motorsports |

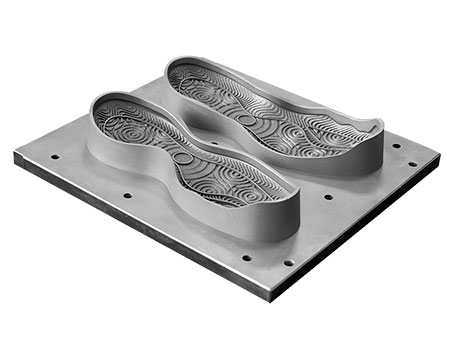

| 🏭Industrial Manufacturing | Injection mold inserts, die-casting cores, and other high-precision tooling | Engine valve seats, transmission gears, brake calipers, and other lightweight wear-resistant parts |

| ⚡Energy & Defense | Nuclear reactor cooling tubes, armor plating, and other corrosion-resistant pressure components | Microchannel heat exchangers, hydraulic manifolds, fuel cell bipolar plates, and other complex fluid systems |

| Characteristics & 利点 | High density (≥99.5%), high mechanical strength, suitable for pure metals (の, アル, stainless steel) | Multi-material compatibility (Ni-based/Ti alloys), controlled porosity (95%-98%), excellent toughness, suitable for complex hollow structures |

Selection Recommendations

| Consideration Factor | Prefer SLM | Prefer DMLS |

|---|---|---|

| 材質の種類 | Pure metals (の, アル, stainless steel) | Multi-component alloys (Ni-based, Ti alloys) |

| Density Requirement | ≥99.5% (load-bearing parts) | 95%-98% (toughness-critical parts) |

| Cost Sensitivity | High-volume production (lower equipment amortization) | Low-volume customization (material flexibility) |

| Post-Processing Limitations | Can accommodate stress-relief heat treatment | Requires retention of controlled porosity functionality |

Important Considerations

Critical Factors

Residual Stress: SLM’s full melting process can generate high residual stresses, requiring support structure design and heat treatment; DMLS sintering generates lower stress but may require infiltration (e.g., 銅) for densification.

Size Limitations: SLM is better suited for larger parts (e.g., aerospace structures); DMLS excels at small-to-medium components with complex features.

Industry Certification: Medical and aerospace applications require compliance with specific standards (e.g., ASTM F2924); verify process certification scope beforehand.

Typical Application Examples

航空宇宙

- SLM: Rocket engine components, satellite brackets

- DMLS: Turbine blades, fuel nozzles

医学

- SLM: Titanium alloy orthopedic implants

- DMLS: Cobalt-chromium alloy dental restorations

Industrial

- SLM: High-precision injection molds

- DMLS: Lightweight automotive components

Technology Overview

SLM Characteristics

- Full melting of metal powder

- High-density parts (≥99.5%)

- Excellent mechanical properties

- Suitable for pure metals & alloys

- Higher build rates

DMLS Characteristics

- Powder sintering (partial melting)

- Controlled porosity (5%-8%)

- Superior toughness

- Multi-material compatibility

- Supports complex internal structures

Key Decision Points

- Part functional requirements

- Material constraints

- Budget & production volume

- Post-processing capabilities

- Industry standard compliance

Compatible Materials

- SLM: Titanium alloys, Aluminum alloys, Stainless steels, Tool steels

- DMLS: Nickel-based alloys, Cobalt-chromium alloys, Titanium alloys, Stainless steels