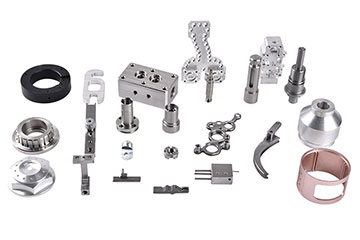

CNC Machining Materials and Corresponding Processes

1. Metallic Materials for CNC Precision Machining and Their Applications

Comprehensive comparison of DT CNC materials (including Aluminum, Stainless Steel, Brass, Steel, and Titanium Alloy), specifications, accuracy, and application areas across different manufacturing processes

| Process | 5-Axis CNC |

| Equipment Designation | 5-Axis Machining Center |

| Common Materials |

|

| Specifications | Various sizes of plates, round bars |

| Common Post-Processing | Spray painting, powder coating, passivation, oxidation, blackening, electrophoretic coating, silk screening, laser engraving, polishing |

| Tolerance Range | ±0.01mm and higher precision requirements |

| Advantages | Multi-surface structures can be formed in one setup, high precision |

| Disadvantages | Limited workpiece size, slower processing speed, light cutting only |

| Primary Applications | Prototyping, automotive, medical, consumer electronics, toys, mechanical equipment, aerospace |

| Max. Workpiece Dimensions | 4000×400×150mm |

| Process | 3-Axis CNC |

| Equipment Designation | CNC Machining Center |

| Common Materials |

|

| Specifications | Various sizes of plates, round bars |

| Common Post-Processing | Spray painting, powder coating, passivation, oxidation, blackening, electrophoretic coating, silk screening, laser engraving, polishing |

| Tolerance Range | ±0.01mm and higher precision requirements |

| Advantages | Fast efficiency, capable of heavy cutting, simple operation, high precision, excellent surface finish |

| Disadvantages | – |

| Primary Applications | Prototyping, automotive, medical, consumer electronics, toys, mechanical equipment, aerospace |

| Max. Workpiece Dimensions | 1500×800×300mm |

| Process | Lathe |

| Equipment Designation | CNC Lathe |

| Common Materials |

|

| Specifications | Various sizes of plates, round bars |

| Common Post-Processing | Spray painting, powder coating, passivation, oxidation, blackening, electrophoretic coating, silk screening, laser engraving, polishing |

| Tolerance Range | ±0.01mm and higher precision requirements |

| Advantages | High precision, excellent surface finish, high efficiency |

| Disadvantages | – |

| Primary Applications | Prototyping, automotive, medical, consumer electronics, toys, mechanical equipment, aerospace |

| Max. Workpiece Dimensions | Ø500mm |

| Process | Sheet Metal |

| Equipment Designation | Sheet Metal Fabrication |

| Common Materials |

|

| Specifications | Various sizes of metal sheets |

| Common Post-Processing | Spray painting, powder coating, passivation, oxidation, blackening, electrophoretic coating, silk screening, laser engraving, polishing |

| Tolerance Range | ±0.1mm and higher precision requirements |

| Advantages | Simple process |

| Disadvantages | Lower precision |

| Primary Applications | Prototyping, automotive, medical, consumer electronics, toys, mechanical equipment, aerospace |

| Max. Workpiece Dimensions | 1500×1000mm |

| Common Materials | Process | Specifications | Common Post-Processing | Tolerance Range | Advantages | Disadvantages | Primary Applications | Max. Workpiece Dimensions |

|---|---|---|---|---|---|---|---|---|

| 5-Axis CNC | Various sizes of plates, round bars | Spray painting, powder coating, passivation, oxidation, blackening, electrophoretic coating, silk screening, laser engraving, polishing | ±0.01mm and higher precision requirements | Multi-surface structures can be formed in one setup, high precision | Limited workpiece size, slower processing speed, light cutting only | Prototyping, automotive, medical, consumer electronics, toys, mechanical equipment, aerospace | 4000×400×150mm |

| 3-Axis CNC | Fast efficiency, capable of heavy cutting, simple operation, high precision, excellent surface finish | – | 1500×800×300mm | |||||

| Lathe | High precision, excellent surface finish, high efficiency | – | Ø500mm | |||||

| Sheet Metal | Various sizes of metal sheets | ±0.1mm and higher precision requirements | Simple process | Lower precision | 1500×1000mm |

2. Plastic Materials for CNC Precision Machining and Their Applications

| Material | Description / Key Properties | Application Scenarios | Typical Use Cases |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene copolymer. Offers good rigidity, toughness, and vibration damping. Cost-effective, but has limited temperature resistance and UV stability. | Electronic enclosures, household appliances, automotive components, prototyping | Robot housing prototypes, door hinge prototypes, consumer electronics housings |

| Acrylic (PMMA) | Polymethyl methacrylate. High transparency and good weatherability. Prone to scratching and relatively brittle. | Optical lenses, display stands, light fixtures, medical devices | Automotive light covers, advertising light boxes, surgical instrument housings, translucent decorative panels |

| Delrin (POM) | Polyoxymethylene. High strength, low friction, excellent wear resistance, and dimensional stability. Poor resistance to strong acids. | Gears, bearings, automotive parts, electronic components | Door lock systems, fuel system components, industrial gears, medical inhalers |

| Nylon (PA) | Polyamide. Good wear resistance, high toughness, and chemical resistance. Hygroscopic (absorbs moisture). | Mechanical parts, gaskets, automotive components, industrial gears | Valve cover caps, transmission gears, wear-resistant spacers |

| PP | Polypropylene. Excellent chemical resistance, high fatigue strength, and lightweight. Low rigidity. | Chemical containers, furniture, automotive interiors, medical devices | Automotive components (e.g., Ford cases), food containers, medical trays |

| HDPEK | High-Density Polyethylene. Impact-resistant, moisture-resistant, easy to process. Low stiffness. | Pipes, storage containers, outdoor furniture, toys | Conveyor system guides, chemical storage tanks, marine buoys |

| PE | Polyethylene (includes HDPE and LDPE). Good chemical resistance and electrical insulation. Low strength. | Packaging, insulating parts, low-load structural components | Packaging containers, insulating housings, simple structural parts |

| PC | Polycarbonate. High impact resistance, transparency, and heat resistance. Susceptible to stress cracking. | Automotive light covers, electronic screens, safety shields, optical components | Headlamp lenses, bullet-resistant glass, electronic device housings |

| PEI (ULTEM) | Polyetherimide. High temperature resistance, high strength, flame retardant. Higher cost. | Aerospace, medical sterilization equipment, electronic insulation components | High-temperature gears, aerospace components, medical tool housings |

| PEEK | Polyether Ether Ketone. Excellent high-temperature performance, wear resistance, and chemical inertness. Challenging to machine. | Aerospace, medical implants, high-performance mechanical parts | Sensor mounting blocks, compressor valve plates, artificial joints |

| POM | Polyoxymethylene (similar to Delrin). Low friction and high rigidity. Often used for precision components. | Precision gears, bearings, automotive accessories | Industrial gears, sliding elements, mechanical components |

Note: The information above is for your reference. Material selection should be further evaluated according to specific engineering requirements (e.g., load, environment, cost).