Detailed List of Mold Types That Can Be Printed by the DT SLM 3D Printer

Detailed List of Mold Types That Can Be Printed by the DT SLM 3D Printer

Metal 3D printing technology, with its remarkable advantages, has been widely applied in various mold manufacturing processes.

The following is a detailed list of mold types that can be printed by the DT SLM 3D printer:

I. Injection Molds

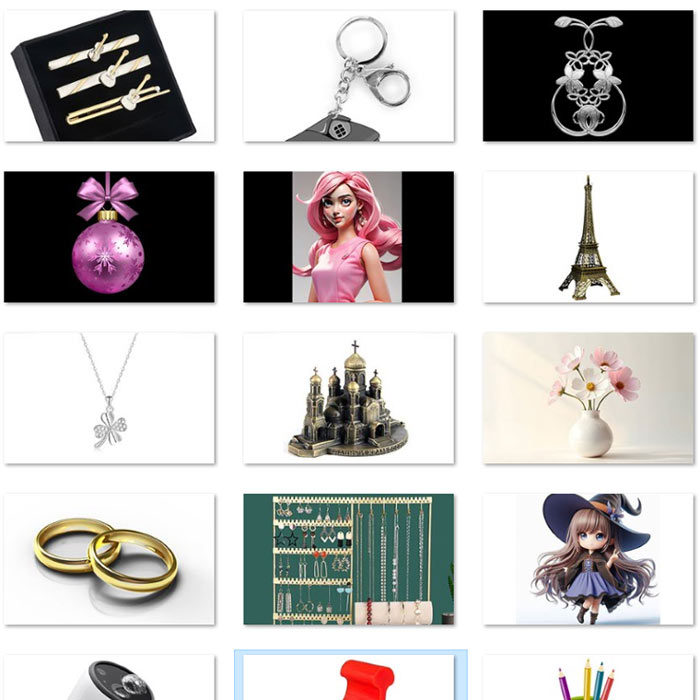

- Conformal Cooling Injection Molds

With metal 3D printing technology, cooling channels that conform to the cavity surface can be directly generated, increasing the cooling efficiency by over 30% and shortening the plastic part molding cycle by 20% – 40%. These molds are especially suitable for products with high requirements for cooling uniformity, such as automotive interior parts and electronic enclosures. - Precision Optical Injection Molds

Optical lens molds printed with DT’s high – polished mold steel (polishing grade A1) can achieve a surface roughness of less than Ra0.05μm. They can meet optical – grade accuracy requirements without subsequent mirror polishing and have been used in the manufacturing of mobile phone camera lenses and medical endoscope lenses. - Insert – type Injection Molds

Through the “grafting process”, complex 3D – printed cores are combined with traditionally machined mold bases. For example, in the mold for the transmission housing of Toyota cars, laser cladding technology is used to print conformal cooling channel inserts on an H13 steel substrate, extending the mold life to four times that of traditional processes.

II. Die – casting Molds

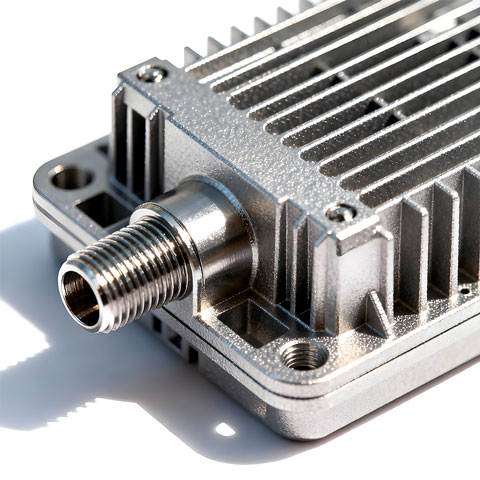

- High – temperature Hot – working Die – casting Molds

DT hot – working die steel specifically designed for die – casting (impact toughness of 35J) can withstand temperatures above 600°C and the erosion of molten metal. Combined with a heatable substrate (pre – heated to 200°C) and multi – laser synchronous printing technology, a large die – casting mold insert with dimensions of 515×485×206mm has been successfully manufactured, increasing the thermal fatigue life by 50%. - Thin – wall Die – casting Molds

Using the 3D – printing unsupported structure technology, complex cooling channels with a thickness of 0.8mm can be directly manufactured, solving the heat dissipation problem of thin – wall molds that is difficult to achieve with traditional processing. This has been applied to the die – casting molds for new energy vehicle battery housings.

III. Forging Molds

- Isothermal Forging Molds

Isothermal forging molds printed with H13 steel. By optimizing the internal reticulated rib structure, while ensuring strength, the weight is reduced by 25%, which is suitable for the precision forging of aerospace titanium alloy blades. - Precision Forging Molds

Combining selective laser melting (GDT) and electrical discharge machining (EDM), precision forging molds with a surface roughness of Ra0.8μm can be manufactured, used for the near – net – shape or net – shape forming of complex forgings such as gears and turbine discs with less or no machining.

IV. Special – forming Molds

- Blow Molds

Blow molds printed with stainless – steel powder are 40% lighter in weight than traditional aluminum molds. With the conformal cooling channel design, the cooling efficiency is increased by 30%. They have been used in the manufacturing of automotive fuel tanks and industrial containers. - Paper – plastic Hot – pressing Molds

Using the breathable steel printing process, micron – sized pores (pore diameter 5 – 10μm) are formed on the mold surface, and heating elements are embedded on the back. This can enable the rapid evaporation of moisture during the hot – pressing forming of paper – plastic products, reducing product bubble defects. - Foaming Molds

The print – free – reduction molds developed for automotive interior foaming parts. Taking advantage of the wear – resistant characteristics of stainless steel, they can be used after simple surface treatment. The mold development cycle is shortened by 60% and the cost is reduced by 50%. - Silicone Molds

3D – printed silicone injection molds can achieve a fine texture replication of 0.1mm, such as the anti – slip patterns of mobile phone cases and the scale markings of medical silicone catheters. The molding accuracy reaches ±0.05mm.

V. Rapid Prototyping Molds

- Direct Metal – printed Prototype Molds

Rapid prototype molds directly printed with superalloys (such as GH4169) can be completed from design to trial – mold within 48 hours, which is suitable for the development of new consumer electronics products. The trial – mold cost is reduced by 70%. - Sand – casting Molds

Combined with binder jetting technology, complex sand – casting molds can be quickly manufactured. For example, a sand – type 3D printer can produce large – scale casting molds for heavy – duty equipment, shortening the delivery cycle from 6 weeks to 2 weeks and reducing the cost by 40%.

VI. Mold Repair and Modification

- Local Repair Molds

Laser cladding technology is used to repair the worn cavity of injection molds. For example, a certain automobile factory uses 17 – 4PH stainless steel to repair the positioning pins of stamping molds, with a hardness of 42HRC and an extended service life of 25%. - Modular Modification Molds

By replacing local modules (such as cores and sliders) of the mold through 3D printing, mold modification can be completed within 3 days. For example, the rapid switch of mobile phone case molds from straight – to – curved surfaces, reducing the modification cost by 80%.

VII. Emerging Application Fields

- Biomedical Molds

Customized surgical guide plate molds for dental implants printed with titanium alloy. Through CT data reverse modeling, they can achieve precise matching with the patient’s alveolar bone, with a surgical accuracy of ±0.1mm. - Glass – forming Molds

Glassware molds printed with high – chromium stainless steel. After surface PVD coating treatment (hardness 2000HV), they can achieve more than 100,000 glass pressings, with a three – fold improvement in anti – sticking performance.

Technical Advantages and Material Innovations

Material Breakthrough: DT offers a range of metal materials (such as high – polished steel, high – thermal – conductivity steel, hot – working die steel) for your selection, and provides various certification reports required by foreign customers (such as CE, FDA/UL, etc.). Among them, the impact toughness of DT’s hot – working die steel is twice that of traditional H13 steel, providing a new option for high – temperature mold applications.

Equipment Upgrade: DT’s SLM metal 3D printer adopts a 2/4 – laser system, with a forming size of up to 400400390mm, supporting various materials such as die steel, aluminum alloy (AlSi10Mg), stainless steel (316L, 17 – 4PH), and titanium alloy (Ti6Al4V).

Process Optimization: The “zero – point positioning” technology realizes seamless connection between printed parts and post – processing equipment, with a positioning accuracy of ±0.02mm, reducing clamping errors. It has been applied in the mass production of automotive molds.